I. Introduction

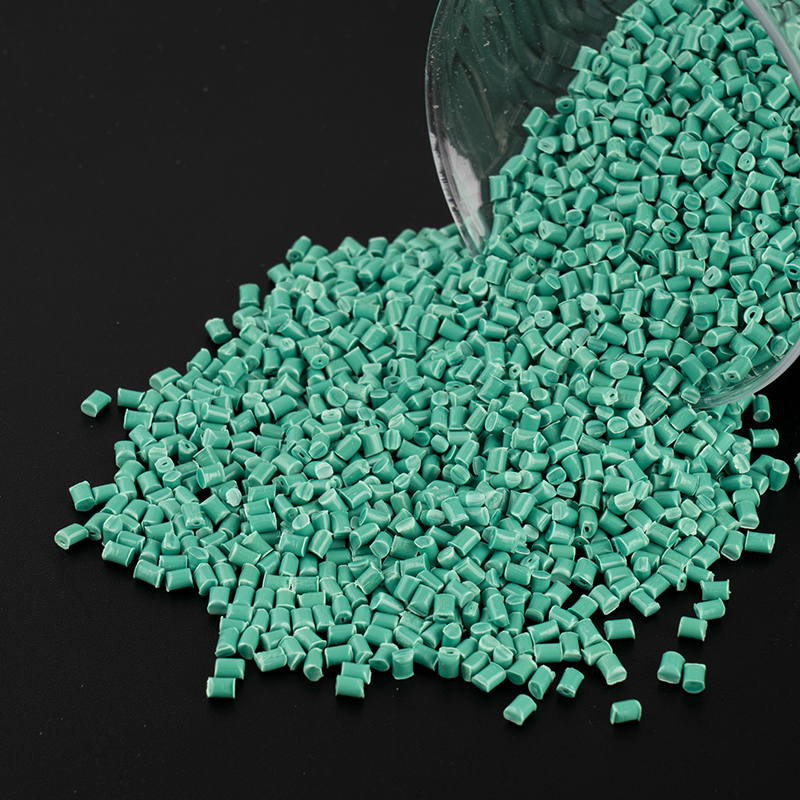

Engineering plastics, ex eorum optimum mechanica proprietatibus, æstus resistentia, et dimensional stabilitatem, late in automotive, electronics, in domum suam appliances, aerospace et medical applications. Cum Industrial upgrades et magis complexu application environments, traditional ipsum plastics sunt luctantem ad occursum quaedam perficientur requisita, ut insufficiens viribus, limitata summus temperatus resistentia, et pauperem flammam retardationis. Ad haec challenges, mutatio ipsum plastics emerged. Modifications of Engineering Plastics per physica vel eget modo, ut supplementi, toughetening, flamma retardancy, electrica conductivity, et scelerisque conductivity, non solum significantly enhance eorum perficientur sed etiam in modum in matris industria.

II. Key perficientur melioramentis in Modified Engineering plastics

Improving Mechanica Properties

Confirmans fortitudinem et rigiditatem: A communi modum addere speculum fibra (Gf), ipsum fibra (cfr), aut mineralibus fillers. Hi auxilia valeat amplio tensile vires, flexal modulum et dimensional stabilitatem plastics. Exempli gratia, speculum alimentorum fibra, faucibus nylon (PA-gf) late in automotive cucullans et anni. Improving lenta et impulsum resistentia: Flexilis Toughening (ut EPDM et EPR), copolymerization Modification, aut Miscens cum Elastomers can amplio plastic in inquisitio, augendae impulsum et in challenging ambitus.

Optimizing scelerisque perficientur

Improving High-temperatus resistentia: Molecular structuram consilio, in introductio aromaticum anulum structurae, et addita ex maxime thermally firmum fillers potest significantly auget calor distorsio temperies (HDT) de plastics. Exempli gratia, Peek Peek late in altus-finem electronics et aerospace.

Enhancing scelerisque conductivity: Et addition of thermally PROLIXUS fillers ut metallum pulveris, Silicon Nitride et Grafene potest amplio scelerisque conductivity de plastics, enabling in usum in applications ut talis ut DUXERIT ENabling in usum in applications, ut DUXERIT ENabling Refrigerant Systems.

Flamma retardancy

Halogen-fundatur flamma retardants: dum effective, ad praesens environmental de et sunt currently declinando in usu.

Halogen-Free Flamma Retardants: phosphoro-fundatur, nitrogen-fundatur, et inorganicis hydroxide-fundatur flamma retardants sunt magis environmentally amica et occursum EU ordinationes ut Rohs et pervenire. Flamma-retardant mutatio materiae sunt praecipue momenti in electronics et automotive interiora sectores. Electrica proprietatibus

Valerius: per purificationem et usum specialized fillers, plastics potest ponere optimum proprietatibus et in electrica concluditur et motricium tecta components.

PROMPTURA PROPIGNUM proprietatibus: by Adding Carbon Nanotubes (cnts), Graphene, seu metallum fibris, PROLIXUS aut antistatic modified plastics potest produci pro electronic et electrica praesidium.

Environmental tutela et sustineri

Bio-fundatur modified plastics: exempli gratia, plastics, plastica, post confirmar et flamma retardant modificatio, potest partialiter reponere petrochemical-fundatur ipsum plastics.

Recyclability et Minimum-Voc Moderation: per Halogen-Free Flamma retardancy, gravis metallum-liberum additives, et corporalis miscere technology, modificatam Engineering plastics sunt in linea cum viridi environmental trends.

III. Typical applications of mutatio ipsum plastics

Automotive industria

Lightweighting: automotive partes sunt paulatim repositoque metallum cum plastics ad redigendum vehiculum pondus et amplio fuel oeconomia. Exempli gratia, speculum alimentorum fibra, confirmat PA et PBT sunt late in engine cucullans, attractio anglicus, ostium tractat, etc.

Novum Energy vehicles: Pugna modules, præcipientes portos et lightweight vehiculum corpora omnia loca superior petit in flammam, retardant, calor repugnant, et thermally PROLIXUS plastics. Electronics et electrica

Maxime calor repugnans, flamma-retardant, et insulating modified plastics sunt primaria materiae ad electrica virgas, bases, cable vaginae et electronic fabrica casings.

Cum progressionem 5G et nova industria industrias, demanda in altus-frequency, humilis-dielectric constant (DK) et low-dielectric damnum (DF) mutatio plastics est celeriter crescente.

Domus appliances et Consumer bona

Modified Engineering plastics Libra AESTHETICA, mechanica vires et diuturnitatem. Exempli gratia, abs / PC Alloys sunt late in TV casings, armarium fores et vacuum lautus housings.

Aerospace

High-perficientur modificatur ipsum plastics ut Peek et Pecps ponere firmum perficientur in summus temperatus, summus pressura, et altus corrosive environments, significantly reducendo aircraft structural pondus.

Medicinae cogitationes

Modified materiae ut PC et Pom sunt in manu chirurgicam et medicamento partus systems, favent ad eorum alta munditiam, sterilizationem resistentia, et biocompatibility.

IV. Future Development trends

Multifunctional Integration: Future modifications non solum focus in meliorem unum perficientur, sed etiam persequi comprehensive statera mechanica, flamma, retardant, calor repugnant, thermally PROLIXUS et electrica proprietatibus. Nanotechnology et Smart Fillers: et addition of Nanomaterials (ut Graphene, CNTs et Nanosilicon) non solum significantly amplio perficientur sed etiam in potentia impertit intelligentes munera (ut auto-sanitatem et sensu).

Green et Sustainable Development: Modified Engineering plastics secundum Bio-fundatur materiae et facti sunt momenti alternative ad traditional petrochemical plastics.

Cost-efficaciam et scalability: Improving perficientur dum redigo costs et consequi magna-scale application sunt clavis ad futurum industriarum.